What Is Hydronics

Hydronics is the use of water as the heat transfer medium in heating or cooling systems.

Properly designed and installed, a hydronic system provides unsurpassed comfort, energy efficiency and design versatility for space heating and cooling of homes and commercial buildings.

Hydronic systems are also used in many heat transfer and recovery applications; domestic hot water heating, snow and ice melting, swimming pool and spa heating, towel warmers, ventilation air preheating, thermal solar panels, ground source heat pumps and waste heat recovery.

Comfort

Hydronic heating can provide the most comfortable indoor environment of any heating system. Comfort is not just subjective, it can be measured in such terms as ambient and surface temperatures, temperature stratification, humidity and the absence of drafts, noise and airborne pollutants.

Forced air heating systems move dust and other airborne pollutants throughout the building. Few hydronic systems involve forced air circulation and those that do create room air circulation rather than building air circulation.

Properly designed and installed hydronic systems operate with virtually undetectable sound levels.

Properly designed hydronic systems control both the air and surface temperature for maximum comfort. They also reduce temperature stratification, further adding to comfort.

Once the advantages of hydronics are experienced, the alternatives will no longer be good enough.

Energy Efficiency

Hydronically heated buildings are much more energy efficient. This has been shown in studies of identical homes side by side, one with forced-air heating and the other with a hydronic system. The difference can be as much as 40%.

The savings are due to factors such as, reduction in pressure differentials that reduce air leakage, absence of temperature stratification that reduce the temperature differential between interior and exterior wall surfaces, lower thermostat setting at which comfort is achieved, and zone control which allows for lowering of temperature in unoccupied zones.

Design Versatility

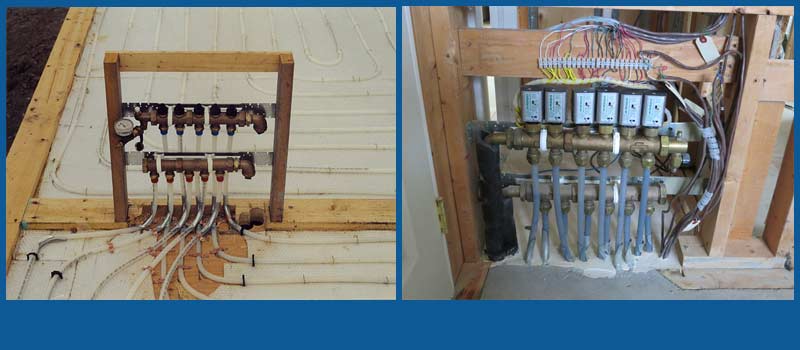

Hydronic systems can be configured in an almost unlimited number of ways to meet the client’s needs, aesthetic taste, and budget. Space heating can be accomplished through a number of heat emitters such as radiant floor (wall or ceiling) heating, panel radiators, fin-tube baseboards and localized air handlers and fan coils.

Hydronic heating systems are easily integrated into any existing or new building. This is especially advantageous where bulkheads are not acceptable or where space is limited. A ¾“ pipe can carry the same amount of heat as a 14” X 8” duct. Flexible PEX piping is easily routed through walls, similar to electrical wiring. This makes hydronic heating very adoptable for retrofits, log homes and any modern energy efficient building.

Hot and chilled water sources

Any number of heat sources can be utilized, including thermal solar panels, ground source heat pumps, boilers and water heaters with any available fuel source. Those fuel sources include natural gas, propane, oil, electricity, wood, biomass and the sun. Heat recovery from waste water or other sources can also be utilized. Several heat and fuel sources can, and often are, combined in the same building.

Chilled water used in air conditioning, cold storage rooms, root, beer and wine cellars usually comes from ground source heat pumps, chillers or deep lake water.

Air conditioning and ventilation when there is no heating ductwork

(The most common objection to hydronic heating)

Many of our clients believed that they would have to give up air conditioning if they chose a hydronic heating system such as radiant floor heating. This is not so. In fact the air conditioning system in a hydronically heated home will deliver superior comfort, energy efficiency and design versatility to a conventional forced-air system.

Any ductwork that is correctly sized for heating will be incorrectly sized for air conditioning. For example a room with a north facing outside wall and a window will have a large heat loss in the winter and a small heat gain in the summer. An identical room facing south will have a large heat loss in the winter and a large heat gain in the summer. If the ductwork is sized for heating than in the summer one of those rooms will be either too cold or too hot.

The placement of registers adds further to his problem. For heating, they are placed where the heat loss is the greatest along outside walls and in the floor. The best placement for air conditioning is in the ceiling and not always at outside walls.

When air conditioning came along the ductwork was already in place for heating. Therefore it was just added to the existing ductwork. The results were not great, but better than no air conditioning. Over time this was accepted as the norm.

When a building has hydronic heating, one is free to provide air conditioning in a way that provides the most comfort and is energy efficient. In most cases this does not involve a single, large, whole house duct system, as is done with heating ductwork. Several smaller conventional duct systems, high velocity (mini duct) systems and radiant cooling systems are the most common options.

As houses became more air tight and whole house mechanical ventilation became necessary, the same pattern was repeated. Ventilation was added to the existing heating ductwork. The results were not great but better than nothing. Over time this became the norm.

In a hydronically heated home, whole house ventilation is done with one or more dedicated and small duct systems. Humidification is accomplished by steam injection directly into the living space. This eliminates duct mold issues and provides excellent humidity control.

The cost of installing hydronic heating

(The second most common objection to hydronic heating)

In most cases hydronic heating does cost more than traditional alternatives such as forced-air furnace. However, the extra costs are to a large degree optional. If a hydronic heating system is built to deliver the same degree of comfort and energy efficiency as a conventional forced-air heating system, the cost is similar or even lower. However, this is rarely done.

With hydronic heating there is a wide choice of heat emitters, heat sources and control strategies. They can be put together in many different ways. People usually want to and do take advantage of this. This is not an apples-to-apples comparison with a forced-air heating system heated by a single furnace and controlled by a single thermostat that delivers limited comfort and wastes energy. Where attempts are made to bring forced air heating closer to the quality of hydronic heating, by introducing zoning dampers for example, the cost difference disappears, but many of the problems inherent in forced air heating still remain.

In new construction, the cost of hydronic heating can be reduced if the building owners plan for it in advance. In most cases building permits are obtained and the construction of the building is well underway before the details of the heating system are looked at. By then options are often limited and the cost of the remaining options is increased. This is especially true for radiant floor heating and ground source heat pump installations.

Smartbuild Inc. can help you design a system that is exactly right for you and your building. If you would like to talk with us about your project please click here.